What Is a Medical Plaster Saw Used For in Orthopedic Practice?

A medical plaster saw is a specialized orthopedic device designed for the safe and efficient removal of plaster casts and synthetic orthopedic bandages.

Unlike conventional rotating cutting tools, a plaster saw uses high-frequency oscillation technology, allowing it to cut rigid casting materials while significantly reducing the risk of injury to the patient’s skin and soft tissue.

Plaster saws are an essential part of daily workflows in:

Orthopedic departments

Trauma and emergency rooms

Outpatient casting clinics

Rehabilitation and follow-up centers

Their role is not only to remove casts, but to do so safely, quickly, and consistently, especially in high-volume clinical environments.

Clinical Applications of an Orthopedic Plaster Saw

Cast Removal After Fracture Healing or Treatment Adjustment

After fracture healing or during follow-up evaluation, plaster casts must be removed accurately and safely.

A professional orthopedic plaster saw enables controlled cast cutting, allowing clinicians to remove immobilization devices without compromising patient comfort or safety.

Removal of Fiberglass and Synthetic Orthopedic Casts

Modern orthopedic treatment increasingly uses lightweight fiberglass and synthetic casting materials.

A medical-grade plaster saw is engineered to maintain stable cutting performance across different cast thicknesses and material densities, ensuring consistent results in daily clinical practice.

Use in Emergency and Outpatient Orthopedic Settings

In emergency rooms and outpatient clinics, rapid cast removal is often required.

Plaster saws support efficient patient turnover, helping medical staff reduce waiting times while maintaining procedural safety.

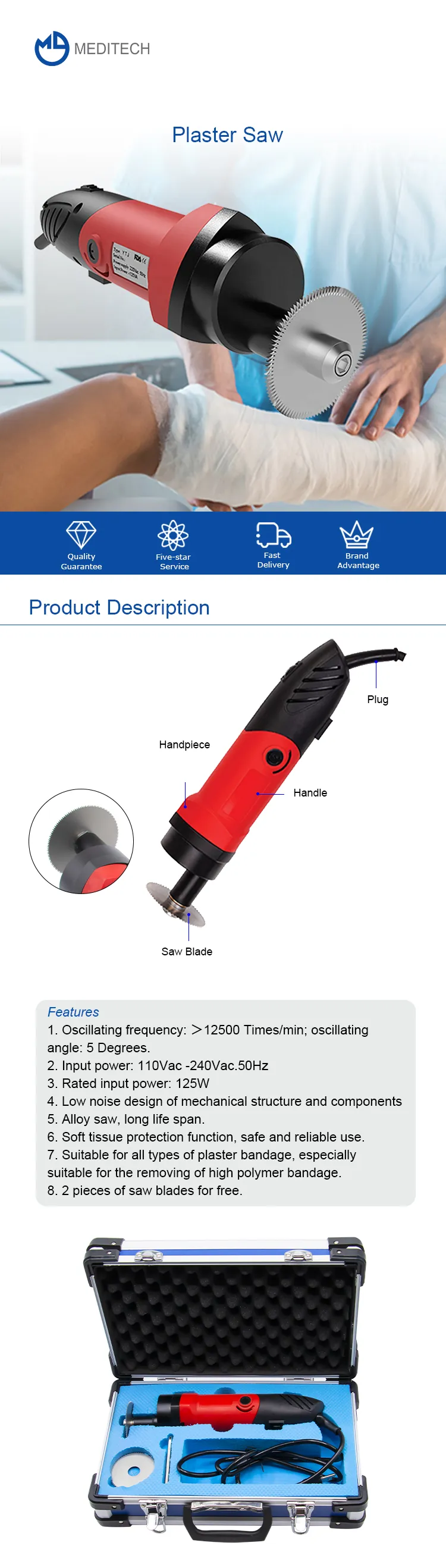

Core Design Features of a Professional Medical Plaster Saw

High-Frequency Oscillation Technology for Patient Protection

The plaster saw operates using oscillating blade movement rather than continuous rotation.

This design allows rigid cast materials to be cut while soft tissues move with the blade, greatly minimizing the risk of skin laceration during cast removal.

Ergonomic Handpiece for Repetitive Clinical Use

The device features an ergonomically designed handpiece, allowing comfortable handling during repeated procedures.

This helps reduce operator fatigue and improves control, particularly in busy orthopedic departments.

Stable Motor Performance for Long-Term Reliability

A durable motor system provides consistent oscillation output, supporting long service life and reliable performance even under frequent daily use.

Blade Compatibility and Cutting Performance

Compatibility with Standard Medical Plaster Saw Blades

The plaster saw is compatible with standard plaster saw blades, enabling hospitals and distributors to source consumables locally without reliance on proprietary blade systems.

Optimized Cutting Efficiency for Plaster and Fiberglass Casts

Blade oscillation frequency and amplitude are optimized to ensure fast, clean cutting through both plaster and synthetic casts, reducing overall procedure time and improving workflow efficiency.

Safety Considerations in Orthopedic Cast Removal

Reduced Risk of Soft Tissue Injury

The oscillating blade design significantly lowers the likelihood of accidental skin cuts compared to rotating tools, making the device suitable for use across a wide range of patient populations.

Controlled Heat Generation During Prolonged Use

The system is designed to minimize heat buildup during extended procedures, helping prevent thermal discomfort and ensuring patient safety during cast removal.

Medical Facility Compatibility and Use Environments

Suitable for Hospitals, Clinics, and Rehabilitation Centers

This medical plaster saw is designed for use in:

Public and private hospitals

Orthopedic specialty clinics

Trauma and emergency departments

Rehabilitation and follow-up centers

Its versatility makes it a standard piece of equipment across multiple orthopedic care settings.

Adapted for High-Volume Orthopedic Departments

Stable performance, ease of operation, and low maintenance requirements make the device well-suited for high-frequency daily clinical use.

OEM, ODM, and Bulk Supply Options for Medical Distributors

OEM Branding and Private Label Solutions

OEM and ODM services are available, including private labeling, packaging customization, and technical configuration based on regional market requirements.

Support for Regional Distribution and Hospital Procurement

The plaster saw can be supplied for distributor networks, hospital tenders, and long-term procurement projects, with consistent quality control and stable supply capacity.

Quality Management and Regulatory Support

Manufacturing Under ISO-Compliant Quality Systems

All plaster saws are manufactured under strict quality management systems, ensuring product consistency, durability, and clinical reliability.

Documentation Support for International Markets

Technical documentation and quality records can be provided to support regional registration, tender submission, and compliance processes in different markets.

Why Choose CZMEDITECH as Your Plaster Saw Supplier?

CZMEDITECH combines orthopedic industry experience, stable manufacturing capability, and global OEM support to deliver reliable medical devices for international partners.

Our plaster saw solutions are developed to meet:

Clinical safety expectations

Distributor procurement standards

Long-term hospital usage requirements

We support partners seeking consistent quality, scalable supply, and professional technical cooperation.

Frequently Asked Questions About Medical Plaster Saws

Is a medical plaster saw safe for patients?

Yes. Medical plaster saws use oscillation technology designed to cut rigid cast materials while minimizing the risk of skin and soft tissue injury.

Can this plaster saw be used for fiberglass casts?

Yes. The device is suitable for both traditional plaster casts and modern fiberglass or synthetic orthopedic casts.

Is OEM or private labeling available?

Yes. OEM and private label options are available for distributors and partners based on order volume and market needs.

What medical facilities typically use plaster saws?

Hospitals, orthopedic clinics, emergency departments, and rehabilitation centers commonly use plaster saws as part of routine orthopedic care.

English

Français

Русский

Español

العربية

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori

नेपाली

Oʻzbekcha

latviešu

অসমীয়া

Aymara

Azərbaycan dili

Bamanankan

Euskara

Беларуская мова

भोजपुरी

Bosanski

Български

Català

Cebuano

Corsu

ދިވެހި

डोग्रिड ने दी

Esperanto

Eʋegbe

Frysk

Galego

ქართული

guarani

ગુજરાતી

Kreyòl ayisyen

Hausa

ʻŌlelo Hawaiʻi

Hmoob

íslenska

Igbo

Ilocano

Basa Jawa

ಕನ್ನಡ

Kinyarwanda

गोंगेन हें नांव

Krio we dɛn kɔl Krio

Kurdî

Kurdî

Кыргызча

Lingala

Lietuvių

Oluganda

Lëtzebuergesch

Македонски

मैथिली

Malagasy

മലയാളം

Malti

मराठी

ꯃꯦꯇꯥꯏ (ꯃꯅꯤꯄꯨꯔꯤ) ꯴.

Mizo tawng

Chichewa

ଓଡ଼ିଆ

Afaan Oromoo

پښتو

ਪੰਜਾਬੀ

Runasimi

Gagana Samoa

संस्कृत

Gaelo Albannach

Sepeti

Sesotho

chiShona

سنڌي

Soomaali

Basa Sunda

Wikang Tagalog

Тоҷикӣ

Татарча

తెలుగు

ትግንያውያን

Xitsonga

Türkmençe

संस्कृत

ئۇيغۇرچە

Cymraeg

isiXhosa

ייִדיש

Yorùbá

isiZulu