The Ultimate Guide to PEEK Anchors: Properties, Applications, and Advantages

If you're looking for a material that can provide superior strength, toughness, and chemical resistance, PEEK (polyetheretherketone) is the perfect choice. PEEK is a high-performance polymer that has become popular in many industries due to its outstanding mechanical properties, biocompatibility, and thermal stability. In this article, we'll discuss PEEK anchors, their properties, applications, and advantages.

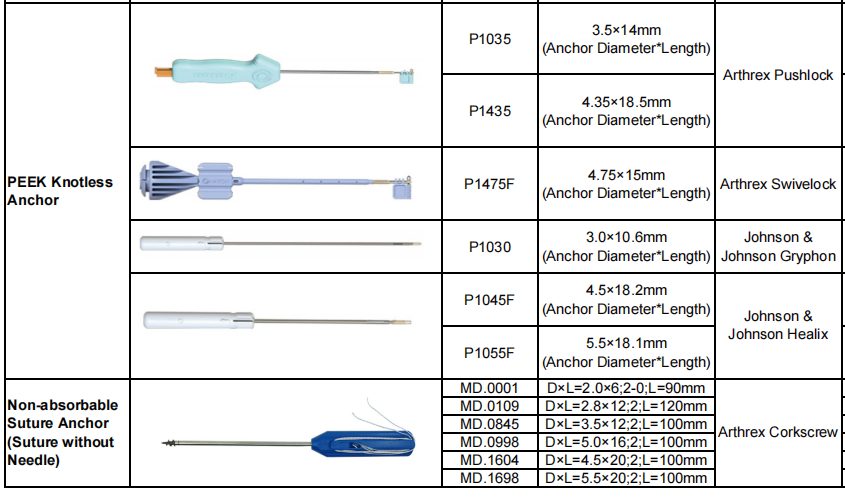

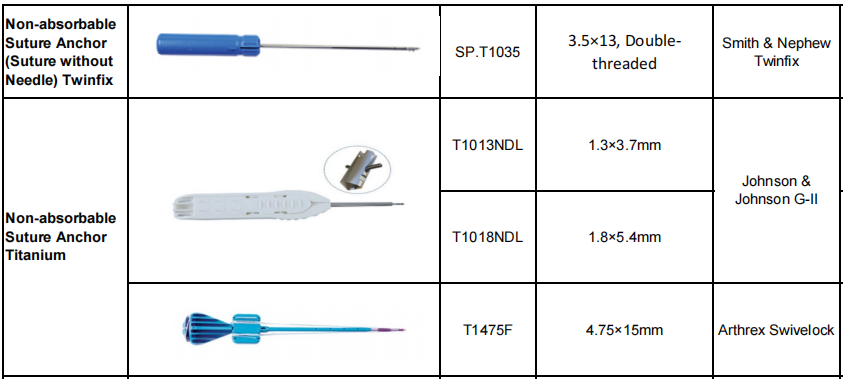

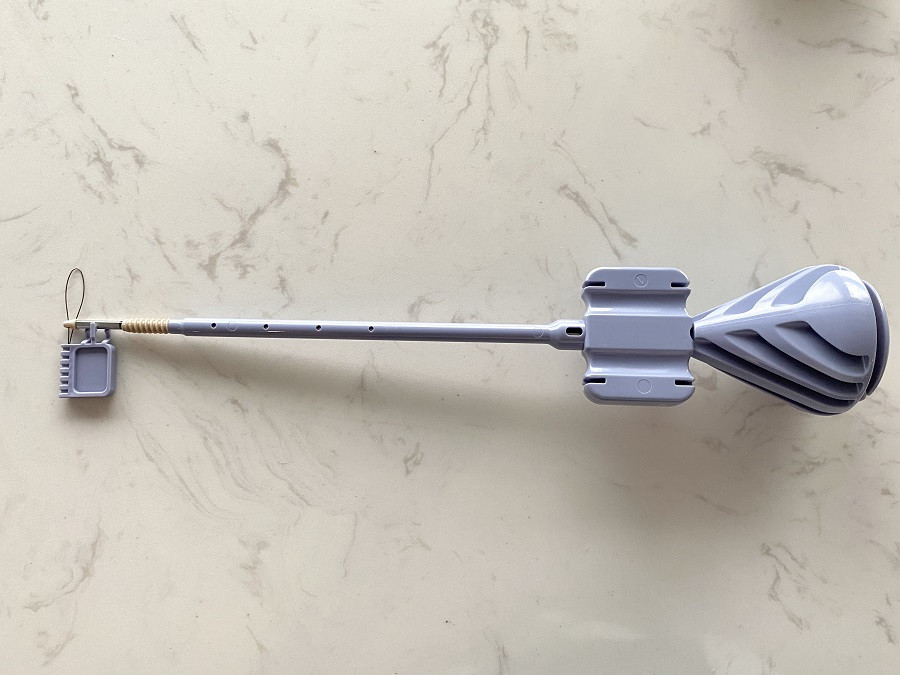

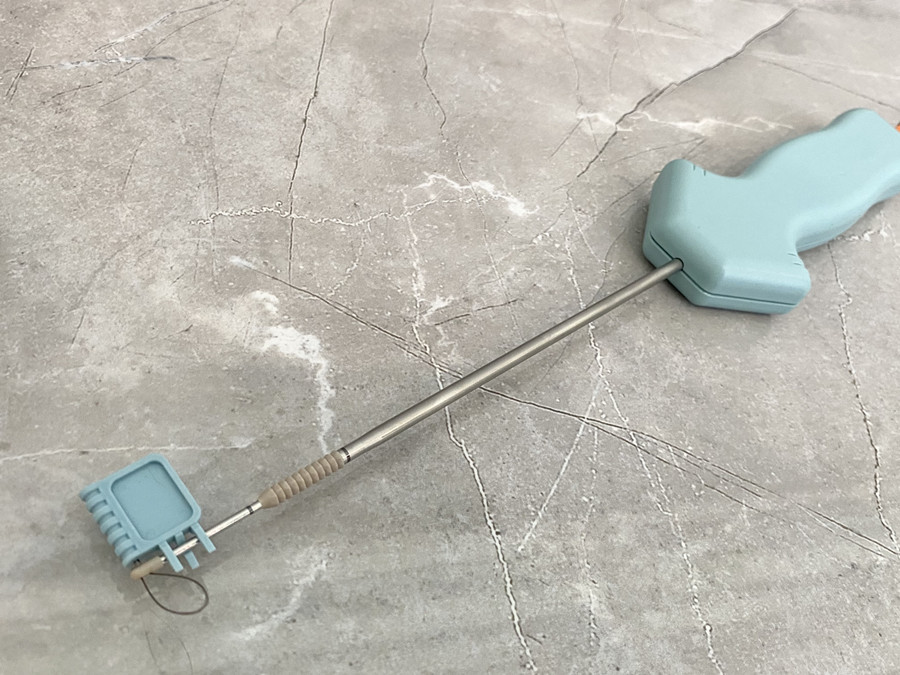

What are PEEK Anchors?

PEEK anchors are fasteners made of PEEK material that are designed to provide strong and reliable anchoring in various applications. They are commonly used in the medical, aerospace, automotive, and oil and gas industries, among others. PEEK anchors are known for their ability to withstand high loads, temperature changes, and harsh environments.

Properties of PEEK Anchors

PEEK anchors have many properties that make them superior to other materials. Some of the most notable properties of PEEK anchors include:

High Strength and Toughness

PEEK anchors have a high tensile strength and toughness, making them ideal for applications that require strong and reliable anchoring. They can withstand high loads and impact without breaking or deforming.

Chemical Resistance

PEEK anchors are highly resistant to many chemicals, including acids, bases, and organic solvents. This makes them ideal for applications where exposure to harsh chemicals is expected.

Thermal Stability

PEEK anchors have excellent thermal stability, withstanding high temperatures up to 300°C without melting or degrading. They are also resistant to cold temperatures, making them ideal for use in cryogenic applications.

Biocompatibility

PEEK anchors are biocompatible, making them safe for use in medical and dental applications. They are also non-toxic and non-carcinogenic, making them an environmentally friendly option.

Applications of PEEK Anchors

PEEK anchors have a wide range of applications, including:

Medical and Dental Applications

PEEK anchors are commonly used in medical and dental applications, such as orthopedic implants, dental implants, and spinal implants. Their biocompatibility and resistance to corrosion and wear make them ideal for use in the human body.

Aerospace Applications

PEEK anchors are used in the aerospace industry due to their high strength and resistance to temperature changes and chemicals. They are commonly used in aircraft engines, avionics, and structural components.

Automotive Applications

PEEK anchors are used in the automotive industry due to their resistance to wear, temperature changes, and chemicals. They are commonly used in engines, transmissions, and fuel systems.

Oil and Gas Applications

PEEK anchors are used in the oil and gas industry due to their resistance to high pressure, temperature changes, and chemicals. They are commonly used in downhole tools, valves, and pumps.

Advantages of PEEK Anchors

PEEK anchors offer many advantages over other materials, including:

Lightweight

PEEK anchors are lightweight compared to other metals, making them ideal for applications where weight is a concern.

High Strength-to-Weight Ratio

PEEK anchors have a high strength-to-weight ratio, making them ideal for applications where high strength is required but weight must be kept to a minimum.

Corrosion Resistance

PEEK anchors are highly resistant to corrosion, making them ideal for use in harsh environments.

Wear Resistance

PEEK anchors are highly resistant to wear, making them ideal for use in applications where abrasion is a concern.

Easy to Machine

PEEK anchors are easy to machine, making them a cost-effective option for many applications.

Conclusion

PEEK anchors are a versatile and high-performance fastener option for a wide range of applications. With their exceptional properties, applications, and advantages, they are becoming increasingly popular in many industries. From medical and dental implants to aerospace and automotive components, PEEK anchors provide reliable and strong anchoring with superior properties that make them stand out from other materials.

FAQs

What is PEEK?

PEEK stands for polyetheretherketone, which is a high-performance polymer known for its excellent mechanical properties, thermal stability, and biocompatibility.

What are PEEK anchors used for?

PEEK anchors are used for reliable and strong anchoring in various applications, such as medical implants, aerospace components, automotive parts, and oil and gas equipment.

What are the advantages of PEEK anchors?

PEEK anchors offer advantages such as high strength and toughness, chemical and thermal resistance, biocompatibility, lightweight, high strength-to-weight ratio, corrosion resistance, wear resistance, and easy machinability.

What are the applications of PEEK anchors?

PEEK anchors have applications in medical and dental implants, aerospace components, automotive parts, and oil and gas equipment.

Are PEEK anchors environmentally friendly?

Yes, PEEK anchors are environmentally friendly as they are non-toxic and non-carcinogenic, making them a safe and sustainable option for various applications.